Organization: Senior Capstone Course

Role: Student Teammate, Research Lead

Timeline: Aug. 2022 – Dec. 2022

Highlights

Challenge:

Bunny Hopkins – a local toy manufacturing startup in Atlanta – needed to differentiate its climbing toys from a flood of other Pikler Triangle style products on the market.

Result & Impact:

My team and I designed and developed a novel climbing structure that helps parents create space amid the clutter and supports kids in years of open-ended play.

Methods:

We employed a quantitative survey to focus on overarching requirements for Bunny Hopkins customers, qualitative interviews to zero in on parents’ needs, and evaluative testing to meet prototypes requirements.

Research Phase

We began the project with limited product criteria from the client. As the design research specialist on our 5-person team, I recommended we begin with needfinding discovery methods to define key criteria for the toy.

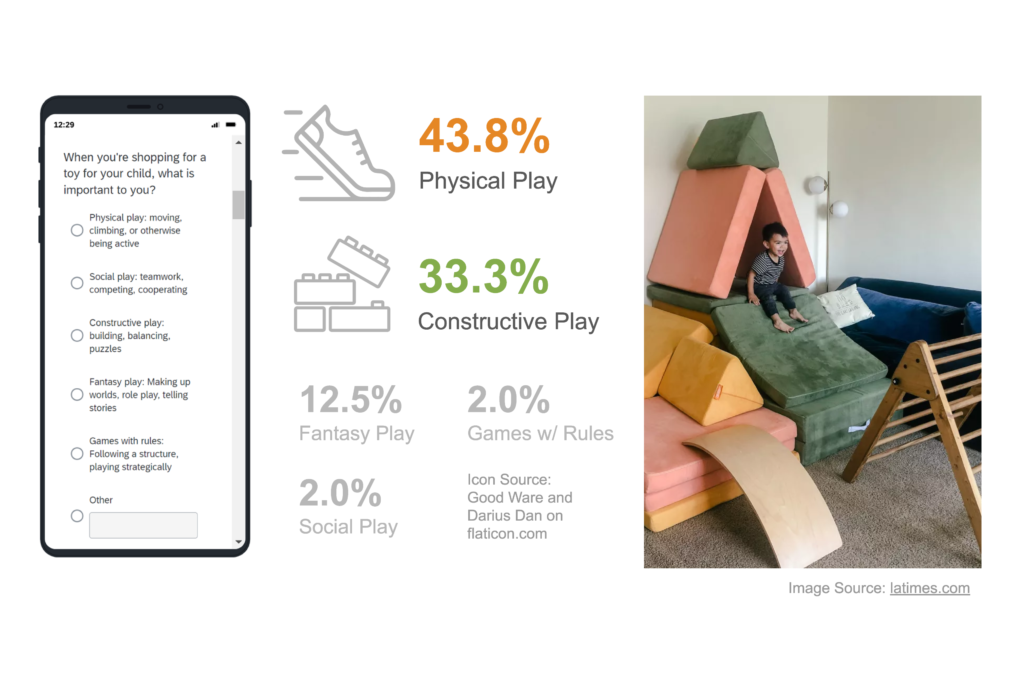

Quantitative Survey

I designed a Qualtrics on survey to answer key research questions in discovery phase:

- What do parents prioritize during / as the outcome of their kids play?

- What does play look like right now? (Kids experience, parents experience)

- How might toys be improved to work better for parents and kids?

The survey screened for parents of kids aged 1-5 and received 49 qualified respondents. Questions like ranked choice of play types helped us narrow the scope of “play.”

Qualitative Interviews

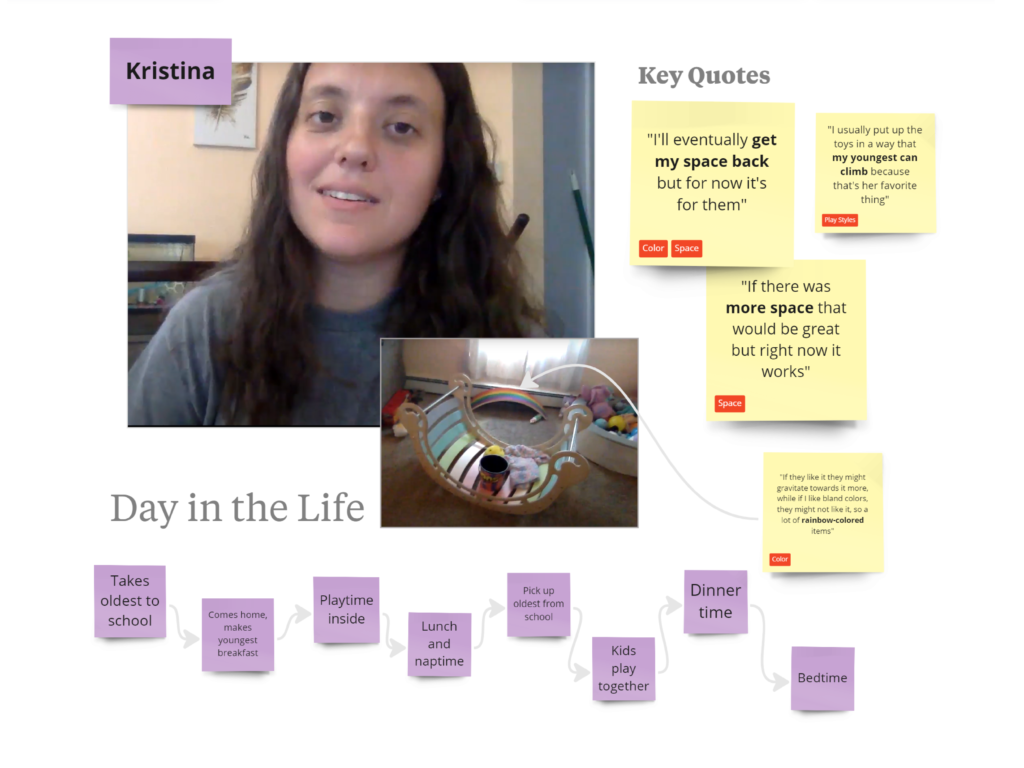

Once we’d focused in on a few play types and pain points, we needed to check our assumptions with some real-world experts.

Parents like Kristina pointed us towards unmet needs with her kids’ toys, such as her wish to “get my space back” and an essential requirement for safety.

I interviewed 8 parents of kids aged 1-5 with my team. Discussion about a day in their life, current frustrations, and descriptions of their space helped us narrow down the contexts of use we would design for. For example, the toy would only be designed for indoor play.

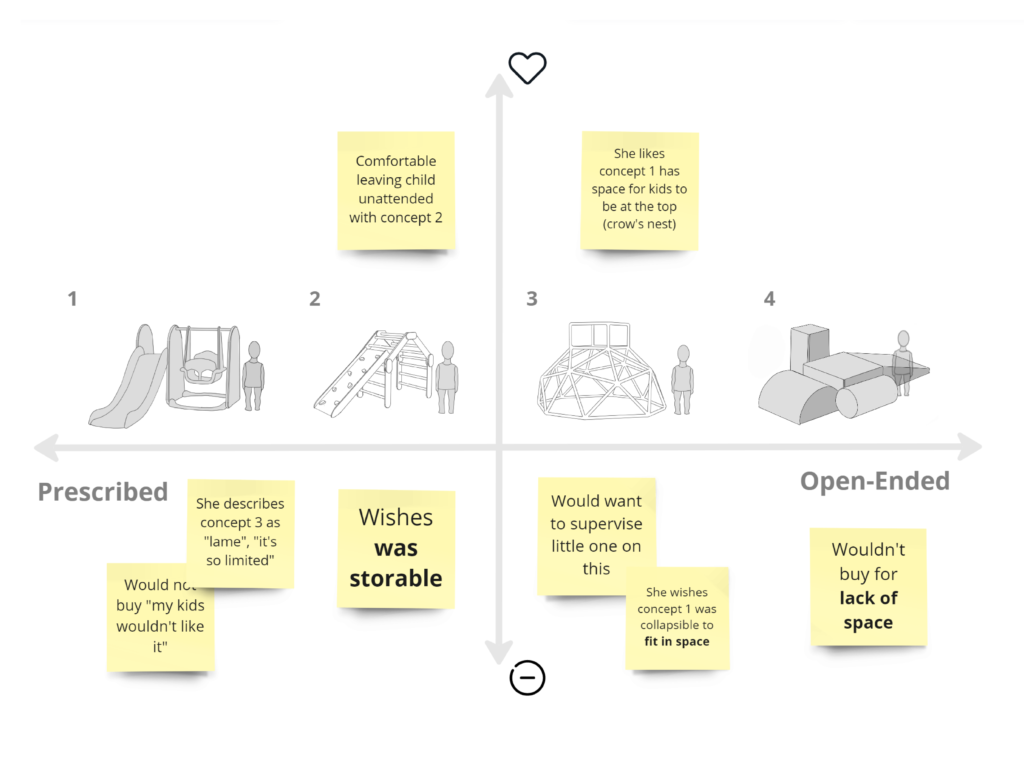

Sketch Review

We also needed to get a handle on what “open-endedness” meant in terms of design criteria. During the interviews, I showed parents a range of 4 “concept sketches” on a spectrum from prescribed to open-ended play to prompt parents’ likes and dislikes.

Parents wanted toys that struck a balance: giving a few easy ways to play right away and options to invent new ways to play as kids spend more time with the toy.

I generated the “concept sketches” from existing products using Sketchbook Pro.

Key Takeaways

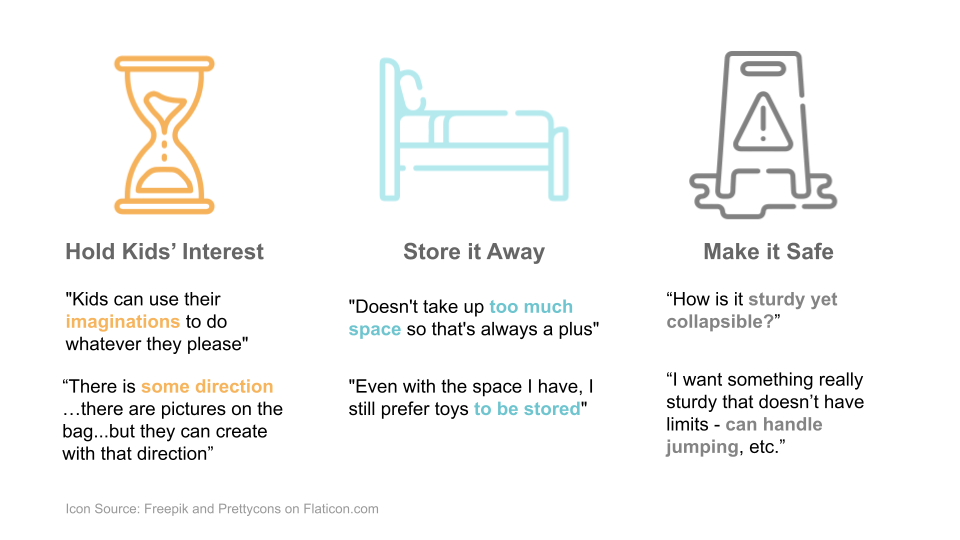

Qualitative research pointed us towards three novel criteria to guide ideation & testing:

- Open-ended: give kids an easy way to start playing with the toy, but leave lots of room for future improvisation

- Rapid storage: making the toy collapse to under 7″ tall to fit under beds

- Safety: meeting toy safety standards (ASTM F963) for kids aged 1-5

Prototyping Phase

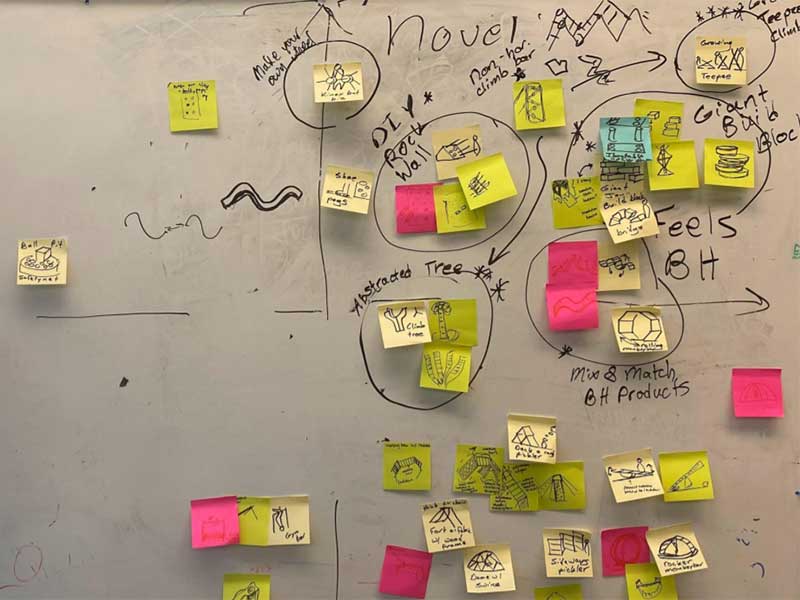

Once we’d defined our three guiding criteria for the toy, we were able to frame brainstorming and option-selection through the lens of which ideas best met all three criteria (or met one very well).

Sketching

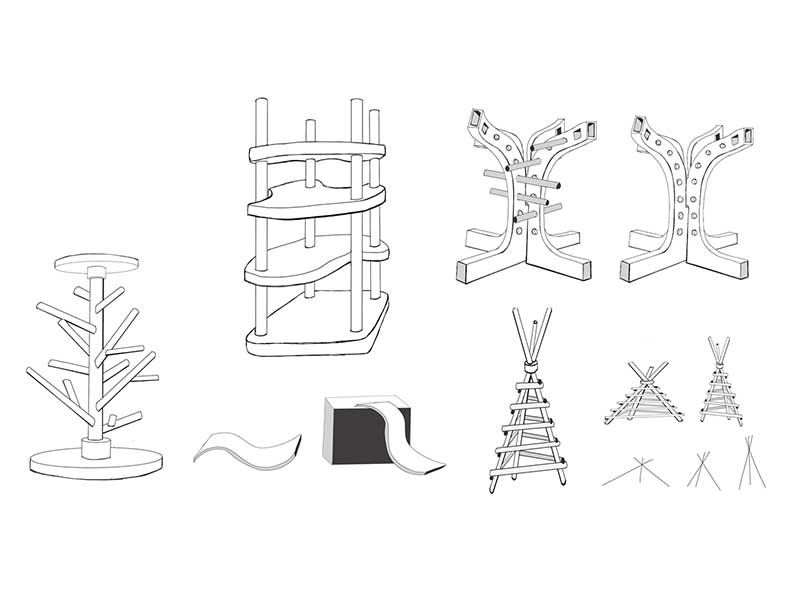

Everyone contributed to brainstorming, and a skilled industrial design teammate generated sketches of the top 5 concepts.

I asked for concept feedback from 3 parents in interviews, and they showed a clear preference for the Tree and Teepee designs.

Renders

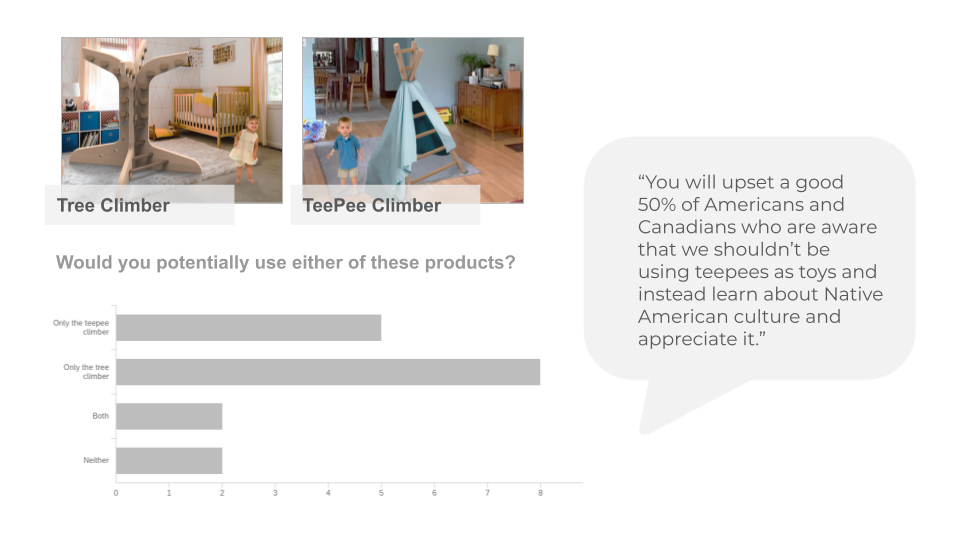

To give parents a chance for more realistic feedback, a skilled teammate generated renders of the 2 preferred concepts.

We shared these out in a survey to parents of kids aged 1-5 to find out how they resonated with parents.

Survey Results

We had more faith in the Teepee concept to meet parents’ need for a rapidly storable toy. While quantitative results showed parents preferred the Tree, qualitative text-box input showed parents may have been more frustrated by the name of the Teepee design than by the toy itself, skewing results.

Recognizing our mistake, we decided to move forward with prototyping and testing of the renamed “Klimb” toy concept.

Testing with Parents and Kids

I shifted roles during prototyping and focused on facilitating concept evaulation with parents. This meant recruiting parents (and their kids) for prototype testing.

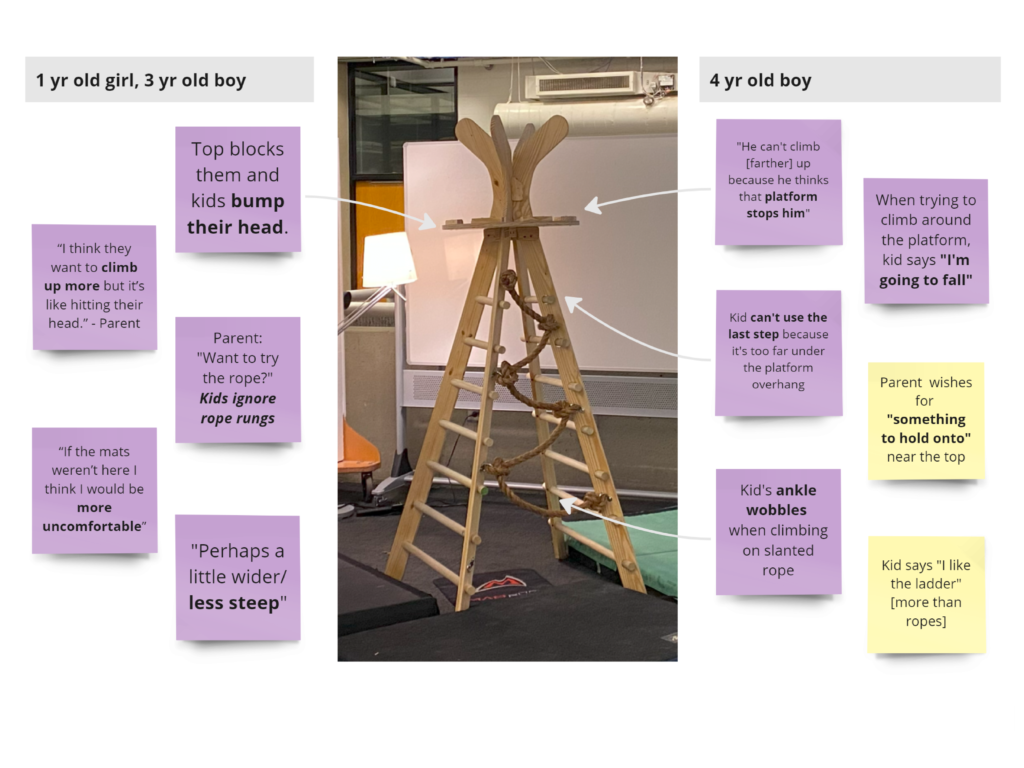

Prototyping to Test

We built a prototype Klimb to facilitate realistic and safe play in a test with kids. That meant building a full-sized and stable (though non-foldable) structure.

Key changes from feedback:

1. Widen the base of the structure

2. Shrink the top platform

I moderated two 30-minute sessions with parents and their kids to gather parents’ feedback as they watched their kids climb, jump, and (terrifyingly) dive from the top platform. We set up rock-climbing crash pads around the toy to prevent injuries from falls.

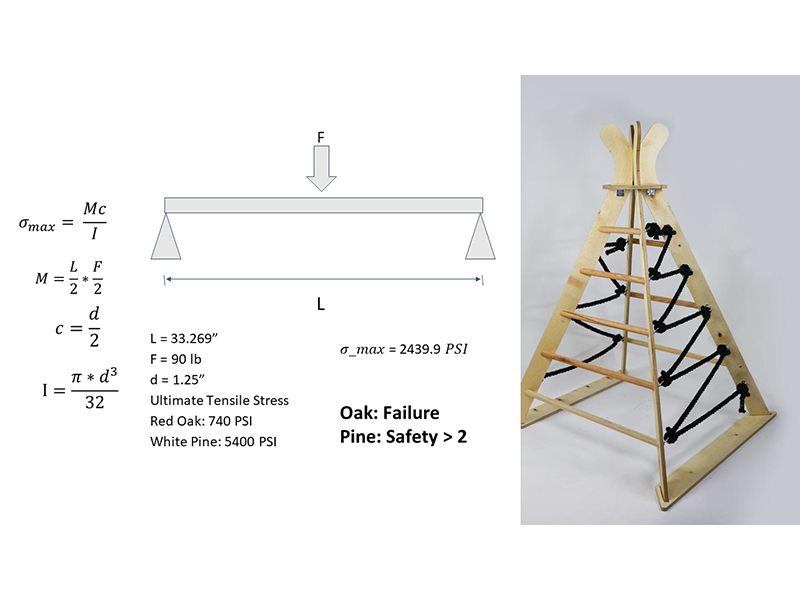

Testing for Failure

One of core goals of our design was safety. In addition to managing research, I contributed my engineering background to define and test potential failure modes of the toy – like failure in bending at the widest rung.

Based on my calculation for bending stress, we changed our rung material from oak to pine to prevent rungs from snapping.

We had observed two kids playing on a toy at a time in our visit to a Montessori School, so I calculated bending at that edge case: two 5 year old kids of 95th percentile weight (CDC data) standing on the widest rung.

Final Delivery

Our project objective was to deliver a proof-of-concept prototype to Bunny Hopkins that differentiated their product line from other Pikler-Triangle-style toys on the market.

Giving Parents Space

The final design – Klime – provides the same open-ended play as a traditional Pikler Triangle with a new recognition for parents’ needs. The toy folds without requiring tools, and slides under beds with 7″ or more clearance. It uses Bunny Hopkins’ signature all natural materials and minimalist design.

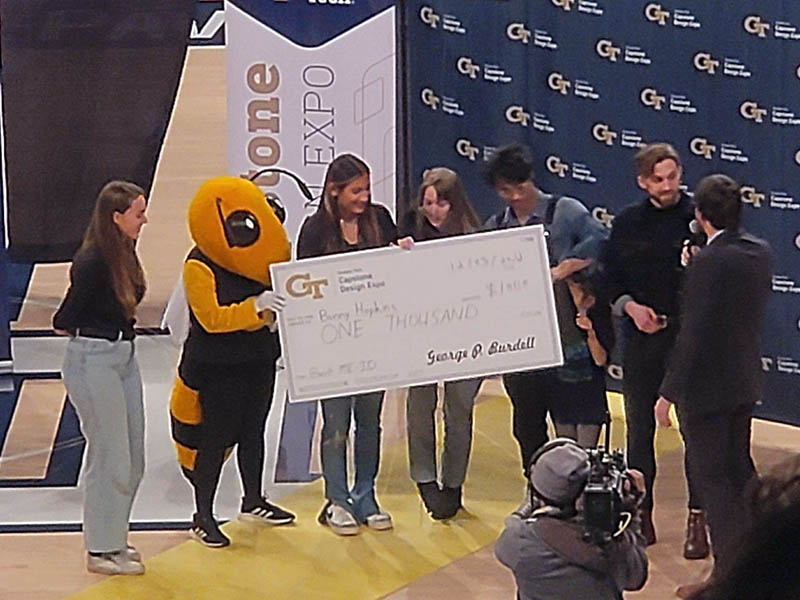

Award-Winning

The design received the award for best project in interdisciplinary engineering & design at Georgia Tech’s Capstone Expo!

A surprising number of young kids attended the Expo with their parents, and most of them spent the whole time climbing on the toy.

The final Klimb prototype, as well as CNC manufacturing instructions, dimensioned drawings, and a priced Bill of Materials, were provided to Bunny Hopkins to support crowdfunding and production for the new addition to Bunny Hopkins’ line of toys.